Service

Proposal for Automation of Work and Measurement Technology for Robotization

![]()

Research and Development of New Technologies

- Web system for steel frame construction

- AR Marker Measurement System

- Inner cross-sectional shape measurement system

- Automatic Roundness Measurement System

- Development of a Visualization System For Tunnel Face

- 3D Modeling and Making of 3D Computer Graphics

Improvement of Work Efficiency

- As-built Quality Control System Using Photo Organizing Software

- Construction and Provision of Measuremnet and Survey Cloud Platform

Design of Various Systems

Optimum design of measurement systems according to the on-site situation

As we employ computer integrated construction utilizing the network browsing of measurement data aiming at improvement in productivity and quality of construction management, the optimally designed measurement systems can be offered according to the on-site situation such as construction procedure.

Constructing the network browsing of measurement data by the use of cloud-based system

It is necessary to process large amounts of measurement data collected from many sites expeditiously to use the network comfortably.

We changed our network from own server-based system to cloud-based system to improve processing speed to a large extent and to take all security measures. Under this comfortable operating environment, we are planning farther reinforcement of services by the use of various contents.

Research and Development of New Technologies

Web system for steel frame construction

Faster data collection becomes possible by data transfer from a smartphone to the server. The former is connected by Bluetooth to the total station which measures location of the steel frame. It enables to understand construction progress, erection or inclination of the steel column at a glance and is also used to span adjustments/exterior works in the post-process or improvement of accuracy in steel frame construction.

Regarding to concomitant surveing with correction of steel column erections, necessary informations such as reference lines, columns,

beams and so on are extracted automatically from the BIM model

generated by "Tekla Structures".

Please contact us if you have concerns about support for CIM.

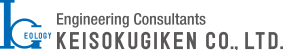

AR Marker Measurement System

※AR markers for surveying attached to steel frames and prestressed concrete are automatically collimated and measured by using a 3D station with camera function.

By extracting material information such as design information, production management

information and inspection information from BIM and CIM models and linking them to

marker IDs, AR markers can be read with a smartphone and all the necessary information

will be extracted easily.

※Industrial Design Registration No. 1675315, International Industrial Design Registration Done

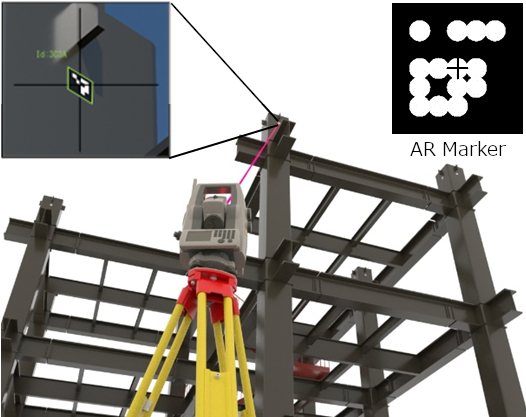

Inner cross-sectional shape measurement system

We realized a high-speed and high-precision automated measuring system for various shapes of inner cross-section using our exclusively developed measuring tool and method with laser distance sensors.

Automated measurement eliminates laboring manual measurement and data input works and improves operability and productivity. By using a mobile terminal which displays measured results instantaneously, prompt and accurate judgements on the next process become possible.

This system is also used as an automatic roundness measurement system for the high-quality and high-precision shield tunnel construction.

Automatic Roundness Measurement System

This is the automatic roundness measurement system.

After completing the shield tunneling, the inner space of the

shield machine is measured by this system.

This is the state of the inner space being measured after

segment assembling is completed.

In this way, excavation, assembly, and measurement are repeated to

maintain high accuracy.

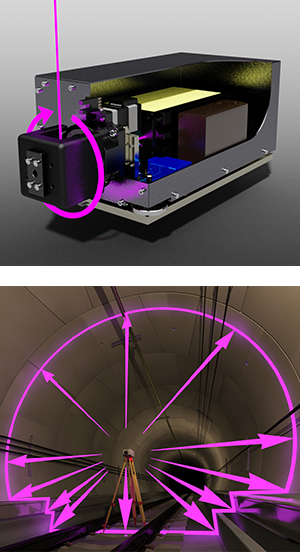

Development of a Visualization System For Tunnel Face

We have realized a tunnel cutting face monitoring and measurement system that has a high-precision laser rangefinder.

By emitting a laser beam horizontally from a distance of up to about 60m and measuring the distance

to the point, the amount of extrusion of the tunnel cutting face based on the measurement data

is monitored, and the deformation status is visualized in real time.

It is now possible to grasp the signs of surface loss, collapse of the tunnel cutting face and to confirm the safety of work.

The number of measurement points could be set from one point to about ten points as needed.